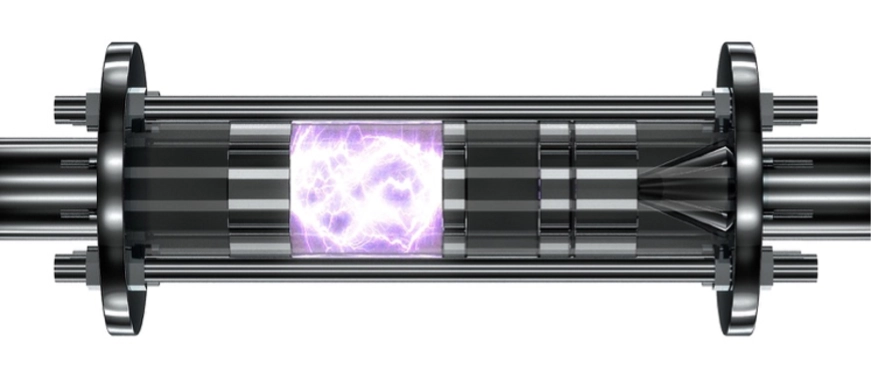

PLASMA-CHEMICAL REACTOR TO PURIFY INDUSTRIAL GAS EMISSIONS BY CONVERSION INTO A HYBRID SYNERGISTIC HIGH-ENERGY HYDROGEN-OXYGEN MIXTURE

Due to the constantly deteriorating environmental situation, the problem of purifying industrial gas emissions from gaseous and dispersed impurities has long been a global problem. Currently, 25 billion tons of carbon dioxide alone enters the atmosphere annually, up to 58 million tons of nitrogen oxide, agents of chemical pollution. According to the World Health Organization, there are about 500,000 tons of such compounds, of which 40,000 tons are harmful substances and about 12,000 tons are ultra-toxic ones.

The most promising trend in the development of technology for cleaning up toxic industrial and energy gas emissions, water treatment and disposal of industrial wastewater is the use of high-energy external fields like cold and high-temperature plasma, ultrasonic wave coherence, multiphase coherence, acoustic-plasma discharge with the formation of a high-energy hydroxyl radical group.

The energy of the electric field affects the physicochemical characteristics of the processed liquid and gaseous medium and its ionic composition, the structure of dissolved organic substances and the viability of the microorganisms present without any additional introduction of chemical reagents.

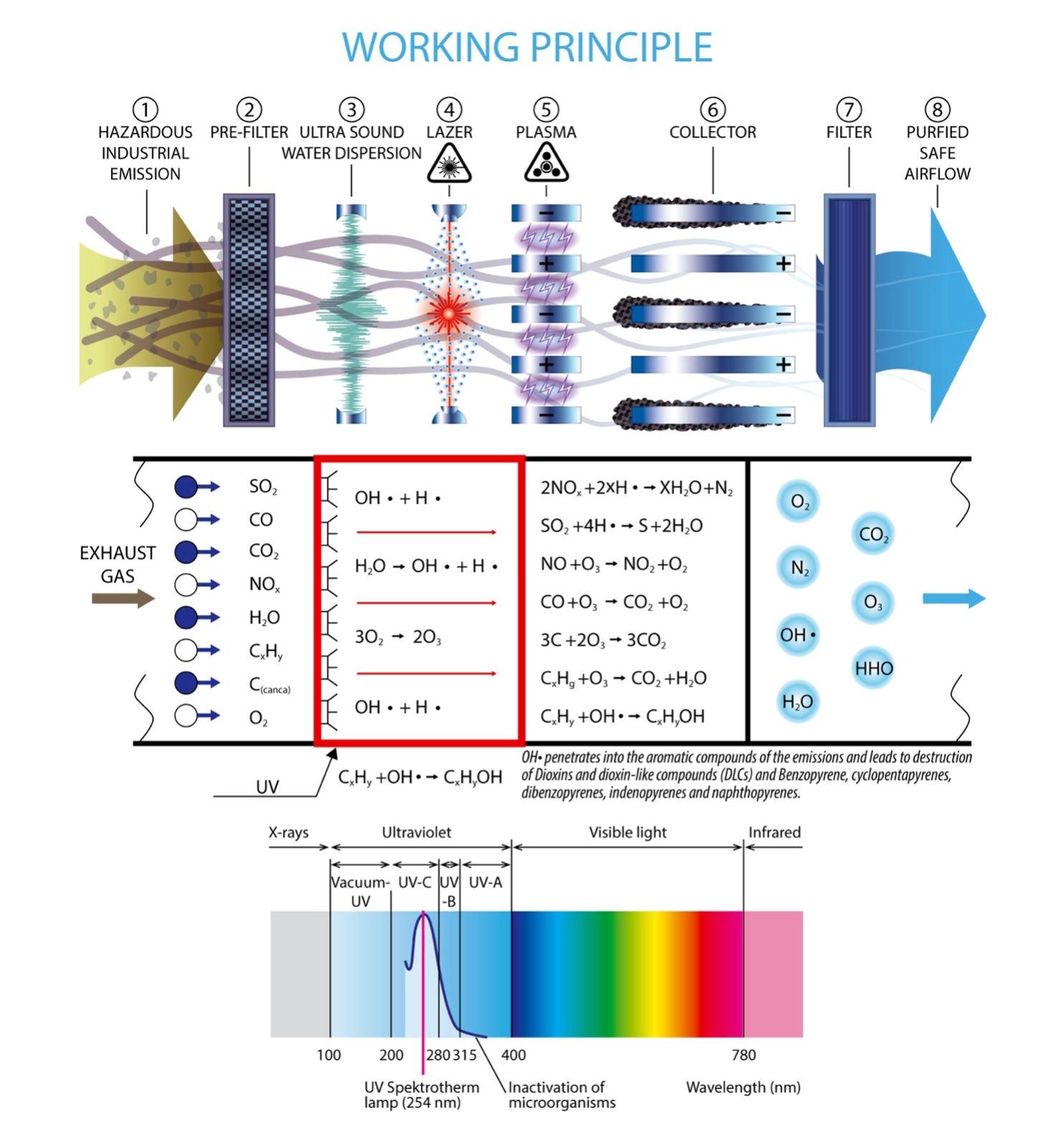

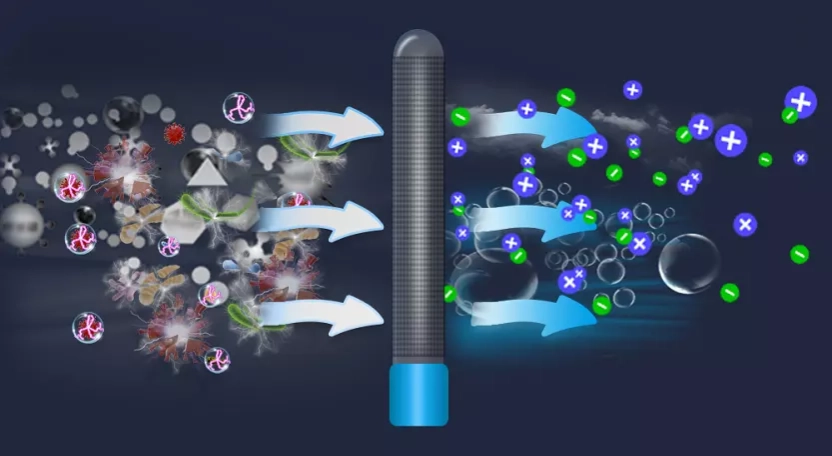

Plasma-chemical process of air filtration

Our laboratory has conducted many research works devoted to the study of the effect of electric (pulse, high-frequency, resonant-combined), hydromechanical and shock-wave fields on the destruction of toxic organic substances in the processed liquid, vapor and gaseous phase media, and also on the disinfecting capacity of the methods.

In a line with the new energy concept, we have developed a completely new conceptual scheme for the complete recycling of gas emissions with the conversion of a gas stream into a high-energy hydrogen-oxygen mixture. Based on theoretical and practical studies, we succeeded to achieve the most complete absorption of radiation energies at resonance at certain exact resonant frequencies of the energies used and the maximum contact of the gas flow passing through the reactor to convert emission gas molecules and water aerosol into “oxyhydrogen”, a gaseous high-energy hydrogen-oxygen mixture. A highly dispersed aerosol of deionized water is added to the exhaust gases of internal combustion engines or industrial emissions gases; being absorbed under the influence of the temperature and electromagnetic field, the converted gas flow enters the plasma reactor, thereby instantly creating its own high-energy atmosphere for the formation of a gas-fuel mixture, WITHOUT USING ATMOSPHERIC AIR!

Water decomposition is considered one of the most promising electrochemical processes for the production of hydrogen-containing fuel mixtures. This presentation describes the practical results obtained for industrial applications, as well as the processes of dissociation of water and water vapor molecules, followed by the formation of hydrogen, oxygen, ozone with the formation of the structuring hydroxyl radical (OH) group when simultaneously using several resonant oscillatory energy fields, cold plasma of dielectric corona barrier and streamer discharge, ultrasonic waves and laser radiation in the presence of an external high-frequency electromagnetic field in a flow reactor.

The flow of cold water vapor in the form of a mono-molecule is produced from an active ultrasonic atomizer and is regulated in the required amount; it is mixed in a vortex flow with an emission source (exhaust gases of internal combustion engines or gas, fuel oil, mixed combustion products of hydrocarbon fuels, gas waste from agriculture) in a vortex chamber without the use of a carrier gas; it enters the reactor at atmospheric pressure and an average temperature of 300 – 1500 degrees Celsius.

The applied high plasma voltage is used in the range of 16 – 20 – 30 Kilovolts depending on the composition and intensity of the gas flow; counter ultrasonic waves pass through the plasma; a specially designed coil creates a pulsed electromagnetic field inside the reactor. Then, the energy of the barrier high-voltage corona discharge is transferred to the molecules in the ionization chamber.

In this chamber, the ionization of the flow molecules occurs; as a result, individual molecules acquire a strong polarization. Each discharge in the chamber consists of several pulses that follow continuously at a given frequency along the same channel; the gas temperature in the spark channel reaches 10,000 K.

Instantaneous strong heating of the gas leads to a sharp increase in pressure and the appearance of shock and sound waves. Each spark channel creates a cascade electron avalanche, and the formed electrons give rise to new avalanches, photoionization processes and excitation of torsion fields occur, during which water-aerosol energy structures are destroyed.

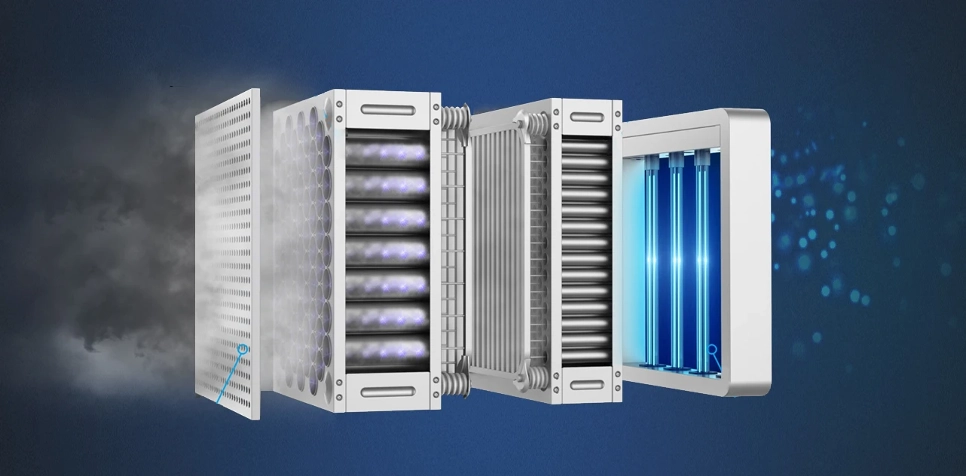

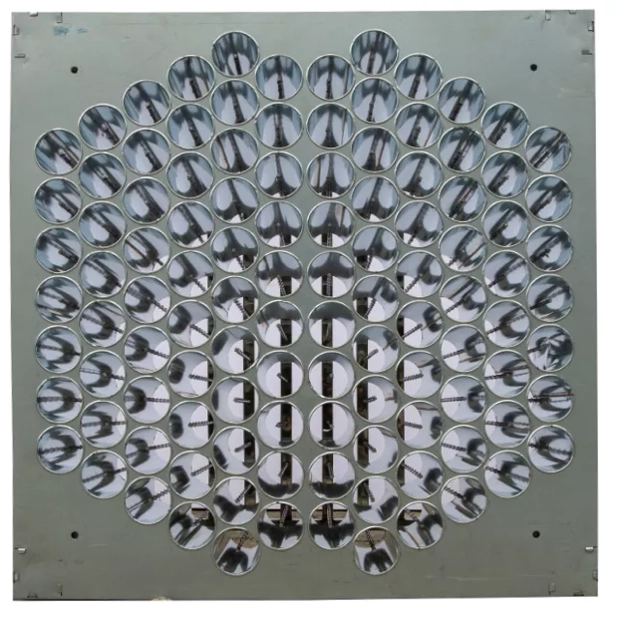

Honeycomb filter cell plasma system

Electromagnets with ferrite cores are located around the circumference of the vortex chamber (for the possibility of working at high circumferential speeds of rotation of the magnetic field). Ferrite has a high magnetic permeability (exceeding magnets by thousands of times) and this makes it possible to achieve large values of the magnetic induction vector. As it is known, the magnetic induction vector has a strictly defined direction, and a certain value of the magnetic field intensity corresponds to its own so-called Larmor frequency of precession of the spin quantum number of a quantum particle. Thus, separate rotating and non-zero magnetic moment protons and electrons are oriented in the created magnetic field in a strictly defined way, i.e. parallel to the axis of rotation. Along with this, a mechanical swirling of the flow occurs according to the principle of the Ranque tube. It is known from the quantum mechanics, that torsion fields are a type of energy more related to the information and energy exchange of matter and space, and due to this, the destruction of molecular information structures occurs. The molecules are already intermediate states on the way to the formation of the final product oxyhydrogen, i.e. high-energy atomic hydrogen and oxygen, which is 3.6 times more energetic than natural gas. As a result, there are many parallel processes of energy-information exchange in the zone of action of torsion fields of resonant oscillatory processes of frequency and amplitude. As it is known, mass is energy.

Air Purification process

For example, it is known that protons, electrons and other constituent parts of atoms simultaneously exhibit the properties of a wave and a solid particle, while they break down into quarks, gluons, fermions, basons and other constituent atomic parts. And each elementary particle has its own energy level and frequency, i.e. in fact, each elementary particle is a clot of energy in the ethereal field. Everything that surrounds us and we ourselves are various concentrations of the wave energy. Thus, if we can transfer energy inside an elementary particle, its mass will increase; and if the mass increases, it will be more difficult for it to oscillate and the frequency of spin oscillations will decrease; the lower the frequency, the more unstable the intramolecular bonds.

Precise settings of the Larmor interaction of frequency and magnetic field allow extremely precise tuning of the vibrational resonance. Given that such processes occur in an intense interferential ultrasonic field, where absorption of the intense ultrasonic radiation by a passing gas stream occurs, this additionally causes a resonance within the molecules resulting in intense dissociation of water monomolecules into hydrogen and oxygen. Additionally, the reactor chamber is subjected to laser radiation to enhance the photon ionization of water molecules. Split laser beams with a wavelength corresponding to the resonance of the excitation of water molecules are fed into the reactor. Thus, at the time of the multiphase reaction, toxic gas emissions are purified, a chemical hydroxyl (OH) group is formed, and this creates a powerful energy hydrogen-oxygen energy cluster, which is a synergistic hybrid ecological gas fuel!

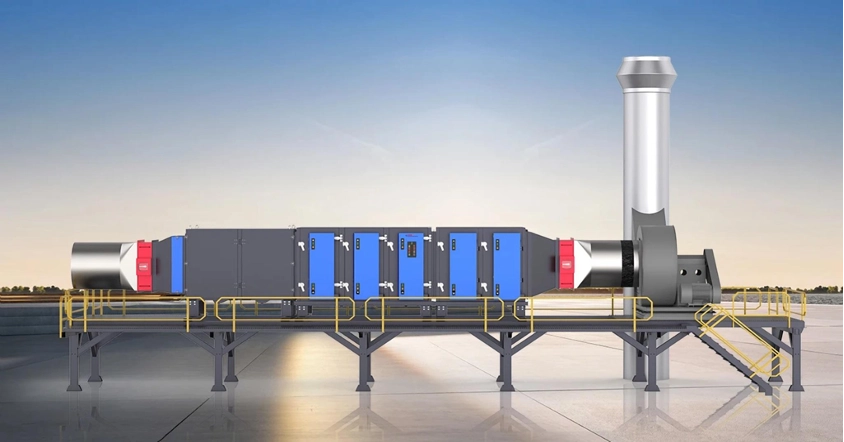

Products for Industrial use

Wide Spacing Electrostatic Precipitator for Industrial Exhaust Emission Control

Industrial Purification Equipment

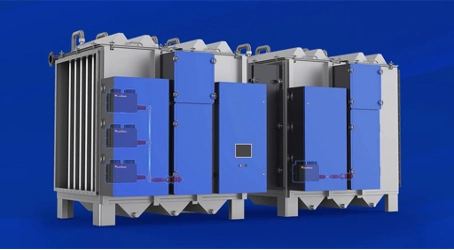

Products for Commercial use

Commercial Purification Equipment

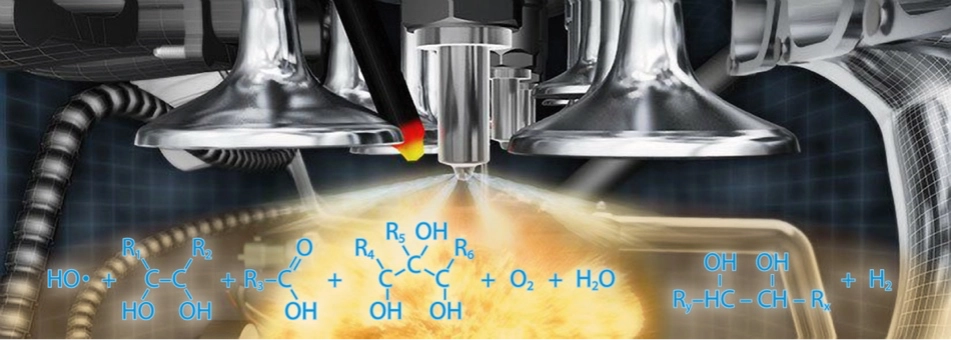

Our laboratory has developed a method for enriching hydrocarbon fuels for use in all types of internal combustion engines and fuel injectors in order to convert all types of internal combustion engines to hybrid multi-phase carbon-hydrogen-oxygen high-energy homogeneous mixtures containing stabilized cluster structures based on the hydroxyl radical; and the essence of the method lies in the sequential processing of the fuel by the hydroxyl radical formed in the presented method under the influence of energy disturbances with different degrees of impact. From a number of experimental data described in the literature, it is known that the hydroxyl radical can be formed from water under the influence of factors leading to dispersion in a strong magnetic field, the reaction proceeds especially easily in the presence of ozone or under the influence of a strong ionizing discharge, such as a corona barrier discharge. The hydroxyl radical formed under different energy conditions has different chemical activity.

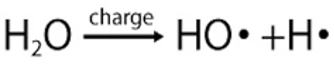

Experimental data show that the hydroxyl radical, which is formed under the conditions of water dispersion, under the influence of ozone in a strong magnetic field, is capable of addition reactions to unsaturated hydrocarbons, i.e. it can exist for a sufficiently long time for this, and the resulting proton immediately dimerizes with the formation of hydrogen:

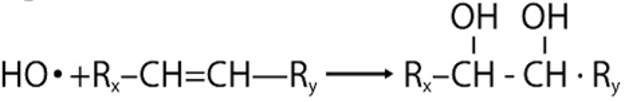

If the reaction of formation of a hydroxyl radical occurs under the influence of a corona barrier discharge of a special frequency, then the resulting hydroxyl radical has a higher energy, triggers a cascade reaction of the formation of similar molecules, and produces reactions associated with the breaking of benzene rings of aromatic compounds with the formation of oxygen-containing aliphatic compounds in newly formed nanoclusters; IR spectroscopy data also indicate the breakage of long paraffin hydrocarbon chains at the locations of tertiary carbon atoms with the formation of the corresponding oxygen-containing compounds.

It is known that a fuel containing saturated aliphatic chains and hydroxyl groups has a number of advantages compared to one that does not contain them. It has also been experimentally proven (IR spectroscopy of water vapor obtained by dispersion with an ultrasonic emitter in a magnetic field for 5-7 hours shows the presence of absorption lines corresponding to the hydroxyl radical and indicates its stable presence) that the hydroxyl radical formed by this method in the presence of water molecules can exist for a long time in the form of cluster structures that maintain such an intermediate compound in a stable form. Combustion occurs in milder conditions, detonation and carbon deposits are reduced. As a result, the environmental performance of the engine improves, the engine life increases. Conducted studies and experiments have shown a tenfold reduction in emission levels for CO, CH. In parallel with the described process, the process of formation of an emulsion from fuel, deionized water, hydrogen, ozone and oxygen takes place.

All processes occur simultaneously, in one or two reactors in series.

Plasma reactor

The technical result of the proposed method is the complete absence of carbon deposits in the working space of the engine, the operation of the engine in milder conditions, the reduction of the engine heat stress, the reduction of emissions of harmful substances into the atmosphere, and significant savings in hydrocarbon fuel.